Every business has a core competency. If you are a manufacturer, you are good at making a product. If you are a retailer, you are good at selling products.

Every business has a core competency. If you are a manufacturer, you are good at making a product. If you are a retailer, you are good at selling products.

Its core competency is the main driver of a company’s revenue. Most of what your business does outside of its core competency takes time and resources away from doing the things that make money.

That fact is the main reason for the popularity of outsourcing. Many businesses realize that by taking on operations that are too far outside their “core”, they run the risk of executing a business operation to which they are not well suited. The problem is compounded by the fact that most companies don’t realize they are not set-up for certain functions until lots of money has been poured down the proverbial sink.

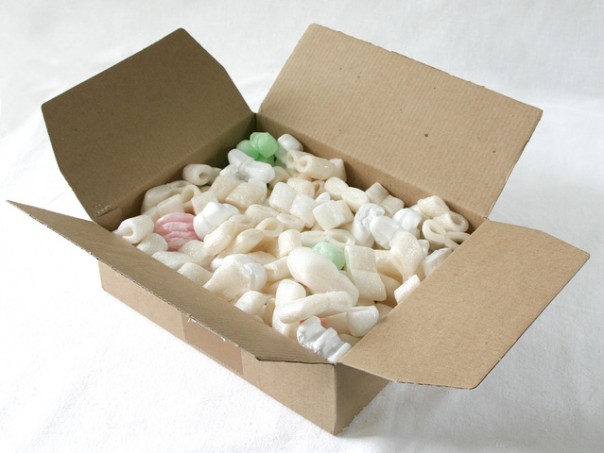

In addition to warehousing, transportation and distribution, co-packing (or contract packaging) is one of the most popular outsourced operations. Co-packing can include re-packing of products from suppliers, adding POP displays, product assembly, product packaging and labelling.

By choosing to use a third-party co-packing specialist, you can enjoy cost advantages that continue to pay off over time.

- Consolidate Costs – Instead of adding additional payroll, equipment and materials that are all outside of your core competency, a co-packing partner takes care of all the details – and costs – in a single expense.

- More Efficient Packaging Design – Incorrect packaging design can be an ongoing drain on your bottom line through extra material in every package and higher shipping costs due to the added weight.

- Value-Added Services – The right co-packing partner will provide end-to-end supply-chain, order fulfillment and transportation services.

By doing what they do best, a co-packing service lets your business focus on what you do best, which means a better bottom line.

CALL US

CALL US